DRINKING WATER TREATMENT

Activated carbon plays a vital role in the treatment of drinking water by effectively removing contaminants and impurities, ensuring safe and clean water for consumption. Here are some key applications of activated carbon in drinking water treatment:

Chlorine and Chloramine Removal:

Activated carbon is highly effective in removing chlorine and chloramine compounds from drinking water. These chemicals are commonly added during the disinfection process to kill bacteria and pathogens. However, residual chlorine and chloramine can impart taste and odor to the water. Activated carbon adsorbs chlorine and chloramine molecules, improving the taste and odor of the treated water.

Removal of Taste and Odor Compounds:

Certain compounds present in water sources can cause undesirable tastes and odors, often resulting from the decomposition of organic matter or the presence of algae and bacteria. Activated carbon adsorbs these taste and odor-causing compounds, enhancing the palatability of the treated water.

Removal of Organic Compounds:

Organic compounds such as pesticides, herbicides, industrial chemicals, and natural organic matter (NOM) can be present in drinking water sources. Activated carbon adsorbs these organic contaminants, reducing their concentration in the water and improving its overall quality.

Micro-pollutant Removal:

Activated carbon is capable of removing micro-pollutants such as pharmaceuticals, personal care products, endocrine disruptors, and volatile organic compounds (VOCs) from drinking water. These emerging contaminants are of growing concern due to their potential adverse effects on human health and the environment.

Reduction of Disinfection Byproducts (DBPs):

Disinfection byproducts (DBPs) are formed when chlorine reacts with organic matter in water during the disinfection process. Some DBPs, such as trihalomethanes (THMs) and halo acetic acids (HAAs), are considered potentially harmful and regulated by drinking water standards. Activated carbon effectively removes precursors of DBPs, helping to reduce their formation and ensuring compliance with regulatory limits.

Decolorization:

In cases where drinking water sources contain color-causing substances, such as tannins and humic acids, activated carbon can be used for decolorization. By adsorbing these compounds, activated carbon helps to clarify the water and improve its aesthetic quality.

Adsorption of Heavy Metals:

Activated carbon has the ability to adsorb certain heavy metals, including lead, mercury, cadmium, and arsenic, from drinking water. This property makes it a valuable tool for mitigating the risks associated with heavy metal contamination and ensuring the safety of drinking water supplies.

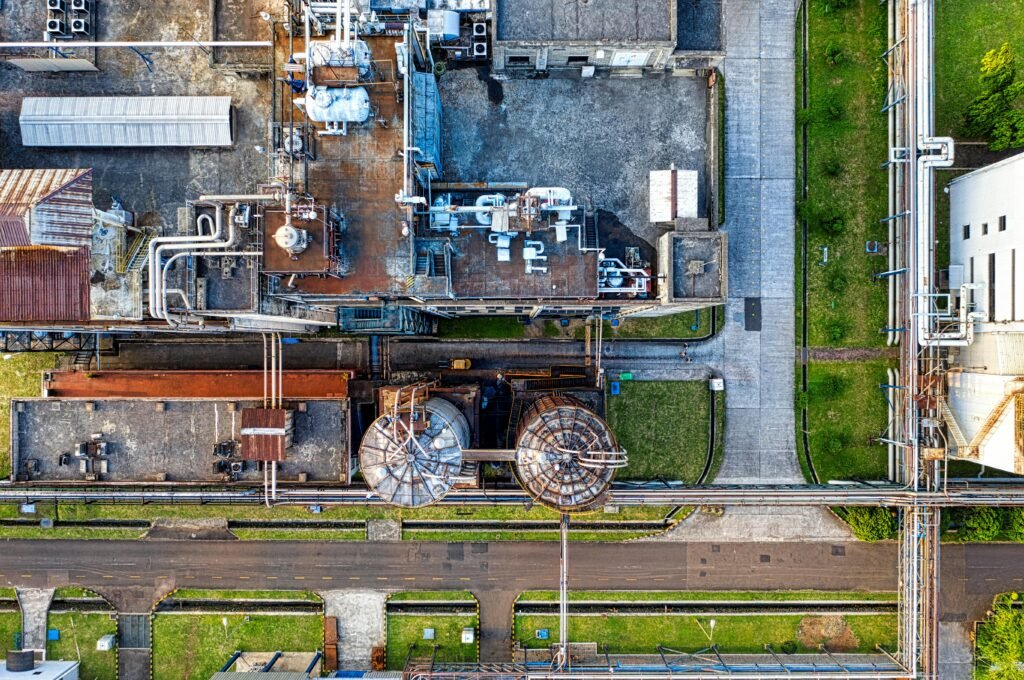

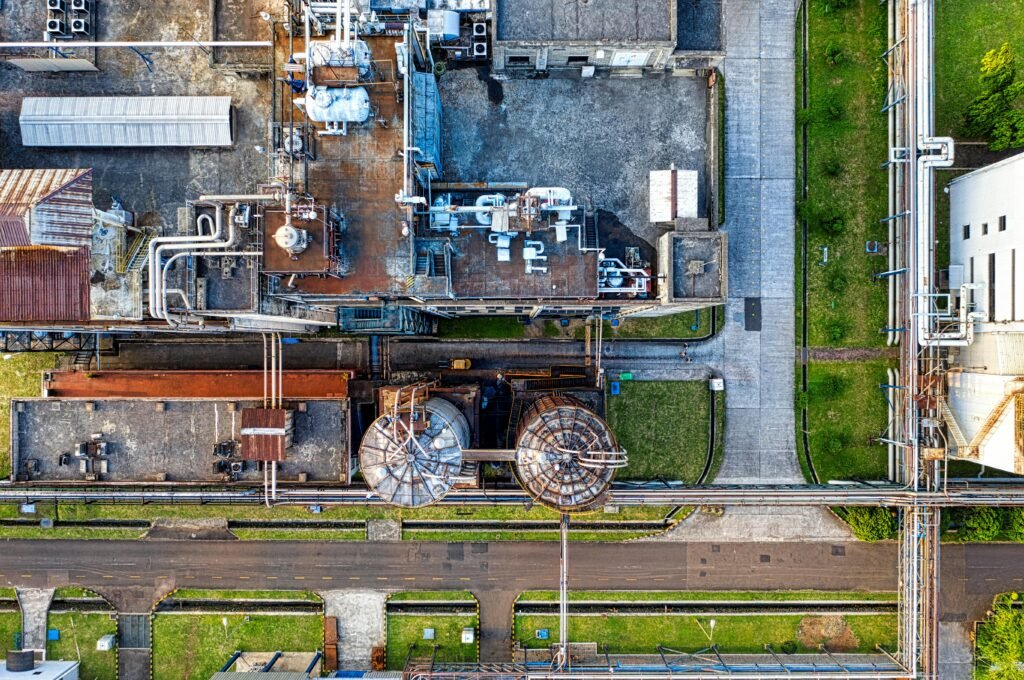

Wastewater Treatment:

Activated carbon is widely utilized in wastewater treatment due to its exceptional adsorption capabilities, which allow it to effectively remove various contaminants from wastewater. Here’s how activated carbon is applied in wastewater treatment:

Organic Contaminant Removal:

Activated carbon is highly effective in adsorbing organic contaminants such as dissolved organic matter, pesticides, pharmaceuticals, and industrial chemicals present in wastewater. These contaminants often contribute to water pollution and can be harmful to the environment and human health. Activated carbon helps to mitigate these risks by adsorbing and removing them from the wastewater stream.

Removal of Taste and Odor Compounds:

Industries such as chemical manufacturing, pharmaceuticals, textiles, and food processing generate wastewater containing a wide range of organic and chemical contaminants. Activated carbon can be integrated into the treatment process to adsorb and remove these contaminants, ensuring compliance with environmental regulations and minimizing the environmental impact of industrial effluents.

Color and Odor Removal:

In many cases, wastewater contains color-causing compounds and unpleasant odors derived from organic substances. Activated carbon is utilized to remove color and odor-causing compounds, resulting in clearer and odor-free water. This is particularly important in industrial wastewater treatment and municipal sewage treatment, where the removal of color and odor is essential for meeting regulatory standards and ensuring the water's acceptability for reuse or discharge.

Advanced Treatment Processes:

Activated carbon is often used as part of advanced treatment processes, including granular activated carbon (GAC) filtration, powdered activated carbon (PAC) addition, and adsorption onto activated carbon media. These processes are typically applied following conventional wastewater treatment methods such as coagulation, sedimentation, and biological treatment to further enhance the removal of specific contaminants and improve the overall quality of the treated effluent.

Removal of Organic Micropollutants:

Activated carbon is effective in removing organic micropollutants, including endocrine-disrupting compounds, pharmaceuticals, and personal care products, which can persist in wastewater even after conventional treatment processes. By adsorbing these micropollutants, activated carbon helps to improve the overall quality of treated wastewater and reduce the potential ecological impacts associated with their discharge into the environment.

Removal of Chlorine and Disinfection Byproducts:

In some cases, wastewater may contain residual chlorine and disinfection byproducts (DBPs) resulting from disinfection processes used in water treatment plants. Activated carbon can be used to effectively remove chlorine and DBPs, improving the taste, odor, and safety of the treated wastewater before it is discharged or reused.

PHARMACY INDUSTRY

In the pharmaceutical industry, activated carbon plays several important roles due to its unique adsorption properties and biocompatibility. Here are some key applications of activated carbon in the pharmacy industry:

Drug Overdose Treatment:

Activated carbon is used in emergency rooms and poison control centers to treat drug overdoses and poisonings. It works by adsorbing toxins and drugs from the digestive system, preventing them from being absorbed into the bloodstream and reducing their systemic effects.

Wound Dressings:

Activated carbon is incorporated into some wound dressings and wound care products for its ability to adsorb wound exudate, toxins, and odor-causing compounds. It helps maintain a clean and moist wound environment, promoting healing and reducing the risk of infection.

Gastrointestinal Disorders:

Activated carbon is sometimes used as an oral medication to treat certain gastrointestinal disorders, such as flatulence, diarrhea, and indigestion. It adsorbs excess gas and toxins in the digestive tract, helping to alleviate symptoms and improve digestive health.

Dialysis Treatment:

In hemodialysis and hemoperfusion procedures, activated carbon is used as a filter medium to remove uremic toxins and metabolic waste products from the blood of patients with kidney failure. It helps to mimic the natural filtration function of the kidneys and improve the patient's overall health and well-being.

Detoxification and Decontamination:

In cases of accidental ingestion of toxic substances or poisoning, activated carbon may be administered orally or through a gastric lavage procedure to help detoxify the body by adsorbing the toxic substances and preventing their absorption into the bloodstream.

Toxin Removal in Animal Health:

Activated carbon is utilized in veterinary medicine for the treatment of poisoning and toxin ingestion in animals. It is administered orally or through stomach lavage to adsorb toxins and prevent their absorption into the bloodstream, helping to save the lives of poisoned animals.

STORAGE OF GAS:

Activated carbon is indeed used in the storage and handling of gases, particularly for the adsorption of various volatile organic compounds (VOCs), odors, and contaminants that may be present in the gas stream. Here are a few key applications of activated carbon in the storage of gases:

VOC Removal in Gas Storage Tanks:

In industries such as petrochemicals, refineries, and chemical manufacturing, activated carbon is often employed to adsorb volatile organic compounds (VOCs) and other contaminants from gases stored in tanks. Activated carbon beds or canisters are installed within the storage tank or along the gas lines to capture and remove VOCs, preventing their release into the atmosphere during storage and handling processes.

Gas Purification and Conditioning:

In some cases, gases stored for industrial or commercial purposes may need purification or conditioning to meet specific quality standards or regulatory requirements. Activated carbon can be used as part of gas purification systems to remove impurities, contaminants, or trace components that could affect the quality or performance of the stored gas.

Odor Control in Gas Storage Facilities:

Activated carbon is utilized for odor control in gas storage facilities where foul odors may be emitted from stored gases. This is common in facilities storing biogas, landfill gas, wastewater treatment gases, and similar applications. By placing activated carbon filters or media beds in the gas ventilation systems, odorous compounds are adsorbed onto the carbon surface, effectively eliminating or reducing unpleasant odors before they are released into the surrounding environment.

Safety and Environmental Compliance:

The use of activated carbon in gas storage applications helps ensure compliance with environmental regulations and safety standards by minimizing emissions of volatile organic compounds (VOCs) and other pollutants. By effectively adsorbing contaminants, activated carbon helps mitigate potential health risks, environmental impacts, and regulatory compliance issues associated with gas storage and handling operations.

STORAGE OF ELECTRIC ENERGY

Activated carbon has garnered interest in the field of energy storage, particularly in supercapacitors and batteries. Although it’s not a primary component in storing electric energy like lithium-ion batteries, it can enhance the performance and efficiency of certain energy storage systems. Here’s how activated carbon is applied in the storage of electric energy:

Supercapacitors (Ultracapacitors):

Activated carbon is commonly used as the electrode material in supercapacitors due to its high surface area and porosity. In supercapacitors, activated carbon electrodes store energy through the electrostatic adsorption of ions at the surface of the electrodes, enabling rapid charge and discharge cycles. The large surface area of activated carbon electrodes allows for higher capacitance and energy storage compared to traditional capacitors, making supercapacitors suitable for applications requiring high power density and quick energy release.

Flow Batteries:

In flow battery systems, activated carbon can be utilized as an electrode material in redox reactions, which store energy in the form of chemical potential. Activated carbon electrodes facilitate the transfer of ions between the electrolyte solutions, allowing for reversible electrochemical reactions and efficient energy storage. Flow batteries are particularly suitable for grid-scale energy storage applications, where high energy density and long cycle life are desired.

Battery Additives:

In certain battery technologies, activated carbon is used as an additive or component to improve battery performance. In lithium-ion batteries, for instance, activated carbon can be incorporated into the anode or cathode materials to enhance the battery's energy storage capacity, cycle life, and safety. Activated carbon additives can help mitigate issues such as electrode swelling, increase the surface area available for lithium-ion storage, and improve the overall efficiency of the battery system.

Capacitive Deionization (CDI):

CDI is a water desalination technology that utilizes activated carbon electrodes to remove ions from aqueous solutions. In CDI systems, activated carbon electrodes adsorb ions from the water when an electric potential is applied, enabling the purification and desalination of water without the need for chemical additives. While not directly related to electric energy storage, CDI technology highlights another application of activated carbon in electrochemical processes.

Chemical Industry

Activated carbon is widely utilized in wastewater treatment due to its exceptional adsorption capabilities, which allow it to effectively remove various contaminants from wastewater. Here’s how activated carbon is applied in wastewater treatment:

Catalyst Support:

Activated carbon can serve as a support material for catalysts in various chemical reactions. The high surface area and porous structure of activated carbon provide ample sites for catalytic activity and enhance reaction rates.

Water Treatment:

Water is extensively used in chemical processes for cooling, washing, and reaction purposes. Activated carbon plays a crucial role in water treatment systems within chemical plants by removing organic contaminants, residual chemicals, and odors from process water streams, ensuring the quality and reliability of water supplies.

Gas Purification:

In chemical manufacturing processes, activated carbon is used to purify gases by adsorbing impurities, such as sulfur compounds, hydrogen sulfide, and other volatile organic compounds (VOCs). This purification process helps maintain the quality of gases used in chemical reactions and prevents contamination.

Odor Control:

Many chemical processes generate strong odors due to the presence of volatile compounds. Activated carbon is employed for odor control and mitigation by adsorbing malodorous compounds from air and gas streams, improving workplace conditions and minimizing environmental nuisance.

Solvent Recovery:

Activated carbon is employed in solvent recovery systems to remove organic compounds from process streams and recycle solvents for reuse. By adsorbing solvents and volatile organic compounds (VOCs), activated carbon helps minimize waste and reduce environmental impact.

Purification of Chemical Feedstocks:

Activated carbon is used to purify chemical feedstocks and raw materials by removing trace impurities, colorants, and undesirable components. This purification process helps ensure the quality and consistency of chemical products manufactured downstream.

Decolorization and Purification:

Activated carbon is utilized in the chemical industry for decolorization and purification of various chemical compounds, including dyes, pigments, intermediates, and specialty chemicals. It effectively removes colorants, impurities, and contaminants, enhancing the quality and purity of the final products.

Liquid Phase Applications:

In addition to gas-phase applications, activated carbon is used in liquid-phase processes within the chemical industry. It can remove organic contaminants, heavy metals, and pollutants from liquid streams, including process water, wastewater, and chemical solutions.

Melting Industry

Activated carbon finds various applications in the melting industry, particularly in metal casting and metallurgical processes. Here are some ways activated carbon is used in the melting industry:

Metal Casting:

Activated carbon is often used to remove organic binders from green sand molds used in metal casting processes. After casting, the molds containing the metal parts are subjected to heat to burn off the binders. Activated carbon can aid in absorbing the combustion by-products and reducing emissions.

Refractory Materials:

Activated carbon can be incorporated into refractory materials used in melting furnaces and crucibles. The addition of activated carbon can enhance the thermal stability and resistance to corrosion of refractory materials, prolonging their lifespan and improving their performance in high-temperature applications.

Metallurgical Processes:

In the steelmaking industry, activated carbon can be used in desulfurization processes to remove sulfur from molten metal. Sulfur can adversely affect the quality of steel, so its removal is crucial in producing high-quality steel products. Helps in Deoxidation, Gas Purification and Metal Purification.

Carbonaceous Reductant:

In some cases, activated carbon can serve as a carbonaceous reductant in metallurgical processes. It can be used to reduce metal oxides to their elemental forms by providing carbon atoms for reduction reactions. This is particularly relevant in processes like iron smelting and ferroalloy production.

Atmospheric Pollution Control

Activated carbon plays a vital role in atmospheric pollution control by effectively capturing and removing various airborne pollutants and contaminants. Here’s how activated carbon is applied in atmospheric pollution control:

Air Filtration Systems:

Activated carbon is commonly used in air filtration systems, including air purifiers, industrial scrubbers, and HVAC filters, to remove volatile organic compounds (VOCs), odors, and other gaseous pollutants from the air. These filtration systems typically contain beds of activated carbon granules or pellets through which polluted air passes. The activated carbon adsorbs pollutants onto its porous surface, effectively purifying the air before it is released into the environment.

Industrial Emissions Control:

Many industrial processes release harmful gases and pollutants into the atmosphere, posing environmental and health risks. Activated carbon is utilized in industrial emissions control systems to capture and neutralize these pollutants. It is particularly effective in adsorbing sulfur dioxide (SO2), nitrogen oxides (NOx), hydrogen sulfide (H2S), and other acidic gases emitted from combustion processes, chemical manufacturing, and power plants.

VOC Removal:

Volatile organic compounds (VOCs) are emitted from various sources such as industrial processes, vehicle emissions, and household products. VOCs can contribute to smog formation and have adverse health effects. Activated carbon filters are capable of adsorbing a wide range of VOCs, including benzene, toluene, xylene, and formaldehyde, helping to reduce their concentration in the air and improve air quality.

Vapor Recovery Systems:

Activated carbon plays a crucial role in vapor recovery systems designed to capture and recover volatile organic compounds (VOCs) and hydrocarbon vapors emitted from storage tanks, loading terminals, and industrial processes. Vapor recovery units employ activated carbon adsorption beds to trap VOCs and hydrocarbons, preventing their release into the atmosphere and facilitating their recovery for reuse or proper disposal.

Catalyst & Catalyst Carrier

Activated carbon finds applications in catalyst and catalyst carrier systems due to its unique properties, including high surface area, porosity, and surface reactivity. Here’s how activated carbon is utilized in catalyst and catalyst carrier applications:

Catalyst Support:

Activated carbon serves as an excellent support material for catalysts in various chemical processes. Catalysts supported on activated carbon offer high surface area and pore volume, providing ample active sites for catalytic reactions to occur. The porous structure of activated carbon allows for good dispersion of catalytic materials, enhancing catalytic activity and efficiency.

Environmental Catalysis:

Activated carbon-based catalysts are employed in environmental applications such as air and water purification, where they catalyze the decomposition of harmful pollutants and contaminants. Catalytic activated carbon filters are used in air purification systems to remove volatile organic compounds (VOCs), odors, and toxic gases through catalytic oxidation reactions.

Gas-phase Catalysis:

In gas-phase catalysis, activated carbon can act as a carrier for catalysts used in processes such as hydrogenation, oxidation, and dehydrogenation reactions. The high surface area and microporous structure of activated carbon enable effective adsorption of reactants and intermediates, promoting catalytic reactions and improving product yields.

Biocatalysis:

Activated carbon supports are used in biocatalytic applications, where enzymes or microbial catalysts are immobilized onto activated carbon surfaces for biotransformation reactions. The porous structure of activated carbon provides a suitable environment for enzyme immobilization, enhancing enzyme stability and activity in biocatalytic processes.

Liquid-phase Catalysis:

Activated carbon-based catalysts are utilized in liquid-phase catalytic reactions, including hydrogenation, oxidation, and hydrolysis reactions in organic synthesis and wastewater treatment processes. The porous nature of activated carbon provides a large contact surface area for interactions between catalysts and liquid-phase reactants, facilitating efficient mass transfer and reaction kinetics.

Hydrogen Storage:

Activated carbon materials are explored as potential catalysts or catalyst supports for hydrogen storage and fuel cell applications. The high surface area and porosity of activated carbon facilitate hydrogen adsorption and desorption processes, contributing to efficient hydrogen storage and release.

AUTOMOBILE INDUSTRY

Activated carbon finds several applications in the automobile industry, primarily related to emissions control, air purification, and cabin air filtration. Here are some key uses:

Vapor Recovery Systems:

Activated carbon canisters are integrated into the evaporative emission control (EVAP) system of automobiles to capture and store fuel vapors from the fuel tank, preventing their release into the atmosphere. This helps reduce hydrocarbon emissions and minimize air pollution.

Air Conditioning System:

Activated carbon is used in automotive air conditioning systems to remove odors, pollutants, and allergens from the air circulated within the vehicle interior. Carbon-based filters help improve the efficiency of air conditioning units and enhance passenger comfort during travel.

Air Purification and Cabin Air Filtration:

Activated carbon filters are utilized in cabin air filtration systems to remove odors, harmful gases, and volatile organic compounds (VOCs) from the air entering the vehicle cabin. These filters enhance the indoor air quality, providing a more comfortable and healthier environment for passengers.

Fuel and Oil Purification:

Activated carbon can be employed in fuel and oil filtration systems to remove impurities, contaminants, and trace organic compounds from gasoline, diesel fuel, and lubricating oils. Clean fuel and oil contribute to improved engine performance, longevity, and reduced emissions.

Exhaust Gas Purification:

In some advanced automotive exhaust systems, activated carbon is employed as a component in catalytic converters or diesel particulate filters (DPF) to capture and adsorb pollutants such as hydrocarbons, nitrogen oxides (NOx), and particulate matter emitted from the engine exhaust. This helps reduce harmful emissions and comply with stringent environmental regulations.

Hydrogen Storage and Fuel Cells:

In hydrogen-powered vehicles and fuel cell applications, activated carbon is utilized as a storage medium for hydrogen gas. The high surface area and porosity of activated carbon facilitate the adsorption and release of hydrogen, enabling efficient storage and utilization in fuel cell vehicles.

Indoor air decontaminations

Activated carbon is widely utilized in indoor air decontamination due to its exceptional adsorption properties and high surface area. Here’s how activated carbon is applied in indoor air purification:

Adsorption of Volatile Organic Compounds (VOCs):

VOCs are organic chemicals that can vaporize into the air and pose health risks when inhaled. Activated carbon filters in air purifiers effectively adsorb VOC molecules, including those from paints, cleaning products, furniture, carpets, and building materials, helping to improve indoor air quality.

Reduction of Formaldehyde and Chemical Pollutants:

Formaldehyde is a common indoor air pollutant emitted by various household products, such as adhesives, furniture, and insulation materials. Activated carbon filters can effectively capture formaldehyde and other chemical pollutants, enhancing indoor air quality and reducing potential health risks associated with long-term exposure.

Mitigation of Indoor Allergens:

Activated carbon filters, when used in conjunction with HEPA (High-Efficiency Particulate Air) filters, can help reduce indoor allergens such as pollen, dust mites, pet dander, and mold spores. By removing allergenic particles and airborne contaminants, activated carbon contributes to creating a healthier living environment, particularly for individuals with allergies or respiratory conditions.

Removal of Odors:

Activated carbon is highly effective in neutralizing and removing unpleasant odors caused by smoke, cooking, pets, mold, and mildew. The porous structure of activated carbon traps odor molecules, preventing them from circulating in the air and creating a fresher and more pleasant indoor environment.

Control of Indoor Humidity Levels:

In some air purification systems, activated carbon can aid in regulating indoor humidity levels by adsorbing excess moisture from the air. By maintaining optimal humidity levels, activated carbon helps prevent mold growth and the proliferation of bacteria and fungi, contributing to a healthier indoor environment.

Absorption of Tobacco Smoke Particles:

Activated carbon filters are effective in adsorbing harmful chemicals and particulate matter present in tobacco smoke. They help reduce the concentration of toxins and carcinogens in indoor air, thereby minimizing the health risks associated with exposure to secondhand smoke.

Food industry

Activated carbon is widely utilized in the food industry for various applications due to its ability to adsorb impurities, odors, colors, and contaminants. Here are some key applications of activated carbon in the food industry:

Decolorization and Purification:

Activated carbon is commonly used to decolorize and purify food and beverage products such as sugar syrups, edible oils, alcoholic beverages, fruit juices, and vinegar. It effectively removes unwanted colors, flavors, and odors, improving the quality and appearance of the final products.

Water Treatment:

Activated carbon is employed in water treatment systems used in food processing facilities to purify and dechlorinate water. It effectively removes chlorine, chloramines, organic compounds, and residual odors, making water suitable for various food production processes and ensuring the quality of finished products.

Food Packaging:

Activated carbon is integrated into food packaging materials such as sachets, pads, and films to absorb odors, moisture, and volatile compounds that can degrade food quality during storage and transportation. It helps extend the shelf life of packaged food products and maintains their freshness and aroma.

Processing of Edible Oils:

Activated carbon is employed in the refining and processing of edible oils to remove impurities, free fatty acids, pigments, and undesirable flavors. It enhances the clarity, stability, and shelf life of edible oils while maintaining their nutritional quality.

Removal of Contaminants:

In the food and beverage manufacturing process, activated carbon helps remove contaminants, impurities, and undesirable substances. It can adsorb pesticides, herbicides, mycotoxins, heavy metals, and other harmful compounds, ensuring product safety and compliance with regulatory standards.

Brewing and Distilling:

In the brewing and distilling industry, activated carbon is utilized for the purification and filtration of beer, wine, spirits, and other alcoholic beverages. It helps remove impurities, off-flavors, and undesirable compounds, resulting in a cleaner and more consistent final product.

Absorption of Tobacco Smoke Particles:

Activated carbon is used in food processing to remove toxins, allergens, and undesirable substances from food ingredients and additives. It helps ensure the safety and purity of food products, especially in cases where potential contaminants may be present.

Sugar Refining:

In the sugar industry, activated carbon is utilized for the decolorization and purification of sugar syrups and refining processes. It helps remove colorants, organic compounds, and impurities, producing high-quality refined sugar products.